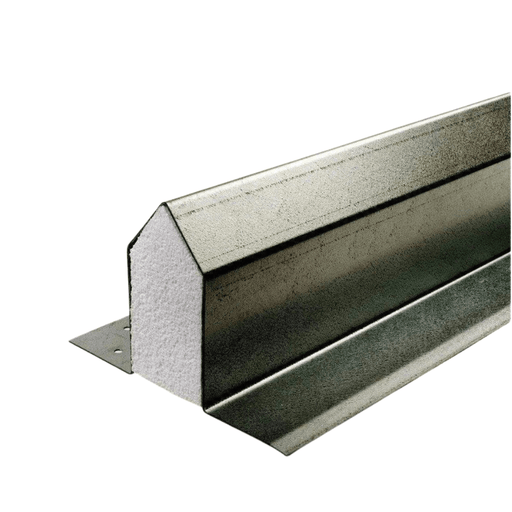

Steel Cavity Wall Lintels

Steel cavity lintels are the top choice for traditionally built brick and blockwork construction projects. The lintels sit invisibly behind the external brickwork while supporting the structure.

Infilled with a polystyrene filler, they reduce condensation and cold bridging too. It is usual for the performance of the steel cavity lintels required on a construction site to be specified by the contractor or client’s architect or structural engineer.

Here’s our brief guide to where to use steel cavity wall lintels.

Lintel Strength

Steel lintels for cavity walls work well because they are generally much stronger than pre-stressed concrete lintels over larger spans. If your opening is greater than 1500mm (4’ 9”), then you will need to use a steel lintel.

Standard Lintels

Use a standard lintel for any door or window opening without secondary loads, such as joist ends for timber floor structures. The rule to follow is triangulation.

If there is a minimum of 600mm (2 feet) of brickwork to each side of the opening and no obstructions above, then a standard lintel should be able to support the triangle of masonry directly above.

Heavy Duty Lintels

If you cannot make up a clear triangle over the opening then your lintel will have to take the entire load of all the masonry overhead. If there isn’t 600mm to either side of the opening, then a heavier-duty lintel should be specified.

A heavy-duty lintel is usually required when the masonry wall is supporting a concrete floor, timber joist ends, attic trusses, or where the opening required is wider than a standard window size.

Your architect or structural engineer should be able to flag up any requirement to go for a heavier specification.

Part L Thermal Break Lintels

Thermal break lintels from Catnic separate the cavity wall masonry leaves, which minimises heat transfer and makes them fully compliant with the Part L energy loss regulations. Simple, yet effective, they are available in standard and heavy-duty specifications.